Unveiling the Excellence of **China CNC Precision Turning Parts**

CNC (Computer Numerical Control) technology has transformed various sectors of manufacturing by enhancing precision, efficiency, and customization. Among the myriad techniques under the CNC umbrella, precision turning stands out, particularly in the context of China CNC precision turning parts. This technology has rapidly evolved, bolstering the production capabilities of metal fabricators globally.

The Rise of CNC Machining in China

China has emerged as a powerhouse in the manufacturing industry, primarily due to its low production costs, skilled workforce, and robust technological advancements. The country's investment in CNC machining has been pivotal in establishing its reputation for producing high-quality components used in various industries.

Key Advantages of CNC Precision Turning Parts

- Unmatched Precision: CNC machines achieve tolerances of up to ±0.005 mm, ensuring that each part is manufactured exactly to specifications.

- Increased Efficiency: Automated processes reduce lead times and increase production rates compared to manual machining.

- Customization: CNC technology allows for the production of highly complex shapes and designs tailored to client needs.

- Consistency: Once programmed, CNC machines produce identical parts with minimal variation, maintaining quality control across batches.

- Reduced Waste: Precision machining minimizes material waste, ultimately lowering costs and supporting sustainability efforts.

Applications of China CNC Precision Turning Parts

China CNC precision turning parts find applications in numerous sectors. Here are some pivotal industries where these components play a crucial role:

Aerospace Industry

The aerospace sector demands high precision and reliability, making it one of the most stringent in terms of manufacturing standards. CNC precision turning parts are integral in producing components such as:

- Engine parts

- Structural elements

- Fasteners and fittings

- Landing gear components

Automotive Industry

In the automotive industry, manufacturers rely heavily on precision parts for improved performance and safety. Applications include:

- Transmission and engine components

- Brake systems

- Steering and suspension parts

- Fuel system components

Medical Devices

The medical field requires parts that meet stringent safety and quality standards. CNC precision turning parts are used in:

- Implants and prosthetics

- Diagnostic equipment

- Surgeons' instruments

- Drug delivery devices

Why Choose China for CNC Precision Turning Parts?

As a business owner looking for high-quality China CNC precision turning parts, understanding the advantages of using Chinese manufacturers is crucial.

Cost Efficiency

Due to lower labor costs and favorable economic conditions, Chinese manufacturers can offer competitive pricing without compromising on quality.

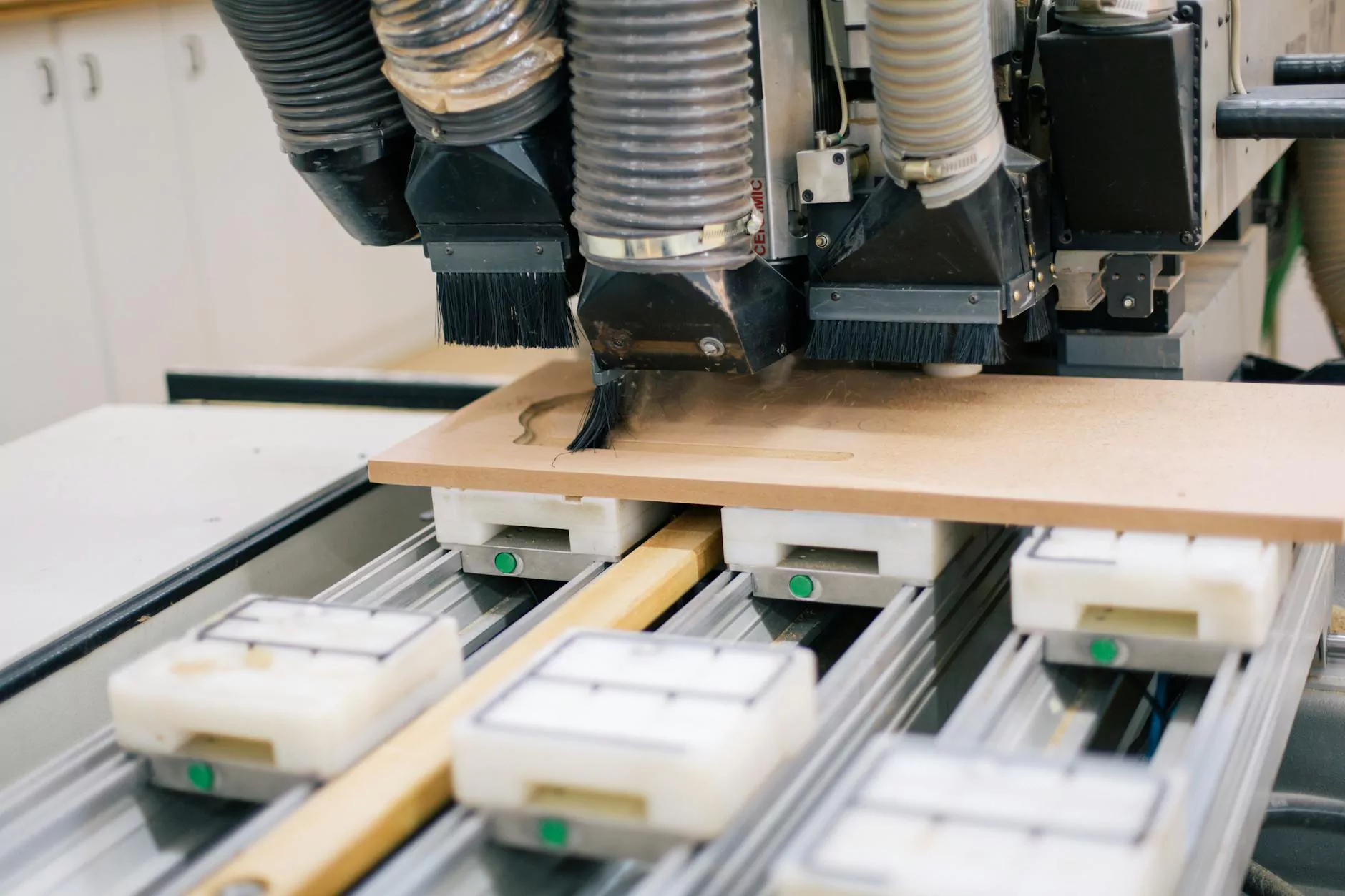

Modern Technology and Facilities

China has invested heavily in advanced manufacturing technologies, ensuring that factories are equipped with state-of-the-art CNC machinery, which is critical for producing precision parts.

Skilled Workforce

The availability of a large pool of skilled workers proficient in CNC machining techniques enhances the capability of Chinese manufacturers to meet international standards.

Supply Chain Efficiency

China's well-established supply chains enable expedient sourcing of materials, reducing lead times for parts manufacturing and shipment.

Quality Control in China CNC Precision Turning Parts Manufacturing

Quality assurance is of paramount importance in the production of CNC precision turning parts. Leading manufacturers implement rigorous Quality Control (QC) processes to ensure that each component meets the necessary specifications. These processes typically include:

Material Inspection

Using high-quality raw materials ensures the durability and reliability of the final product. Manufacturers conduct inspections of incoming materials and apply stringent quality standards.

Dimensional Accuracy Checks

Regular checks are performed using gauges, calipers, and coordinate measuring machines (CMM) to verify that parts conform to design specifications throughout production.

Final Inspection and Testing

Before shipment, every piece undergoes a final inspection to assess functionality and structural integrity, ensuring that only the best products reach customers.

Future Trends in CNC Precision Turning Parts Manufacturing

The landscape of CNC precision turning parts manufacturing continues to evolve. Here are some trends that are shaping the future:

Automation and Smart Manufacturing

Advancements in automation and the integration of AI in CNC machining are enhancing precision and efficiency. Smart manufacturing offers real-time monitoring and adjustments, leading to significant improvements in production capabilities.

Sustainability Practices

As industries grow increasingly aware of environmental impacts, manufacturers are implementing sustainable practices, such as recycling scrap material and using eco-friendly production techniques.

Customization and Additive Manufacturing

With the rise in consumer demand for tailored solutions, companies are investing in flexible CNC systems that can handle custom jobs alongside mass production. Additionally, integrating additive manufacturing can complement turning processes, allowing the creation of more complex geometries.

Conclusion: The Value of China CNC Precision Turning Parts

The role of China CNC precision turning parts in various industries cannot be overstated. Their unmatched precision, versatility, and cost-effectiveness make them indispensable in modern manufacturing. Whether you are in aerospace, automotive, or medical devices, partnering with reputable Chinese manufacturers can significantly enhance your product quality and operational efficiency.

For businesses seeking to stay competitive, embracing the advantages of China CNC precision turning parts will undoubtedly lead to superior outcomes. Invest in precision, invest in quality, and watch your business thrive.

For more information about our services in metal fabrication and CNC turning parts, visit deepmould.net.